The project aimed to find a technological solution for sorting of filled yoghurt cups

Until then yoghurt sorting into customer cartons had been done by manual handling and manual sorting by an operator. This is a considerable burden in terms of the production of thousands of cups all the same while presenting significant time and financial demands.

The aim of the project was to create a brand new to this problem where the goal is to automate the handling and placing of fragile cups filled with yoghurt in a precisely determined position in the cardboard box without damaging either the container envelope or the box itself.

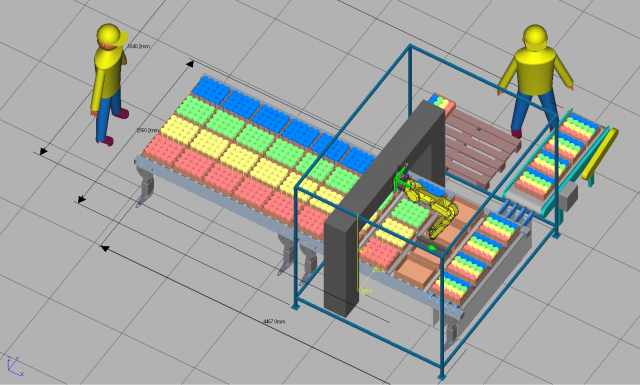

Workplace description

- 4 input conveyors + 1 output conveyor

- the operator places cardboard boxes with single-type yoghurt onto the input conveyors

- each of the input conveyors is designed for 1 type/flavour

- at the end of the conveyors the row of cartons is moved to the transverse output conveyor

- FANUC M-10iA/10M robot, suspended on a steel wall-mounted construction

- using the tentacles the robot always takes a row of yoghurts from 1 carton and transfers them into other cartons according to customer requirements